Why are parametric studies important?

Parametric studies are crucial for engineers as they allow them to vary the power system conditions to account for unknowns, uncertainties, or different operating conditions; therefore, parametric studies are a must on several applications, such as:

- Interconnection with the regulatory pre-defined scenarios

- Finding worst-case scenarios

- Establishing maximum withstand capabilities

- Setting the best control/protection settings

- Getting the impact of parameter uncertainties

- Contingency analysis (n-1, n-2, ...)

- Etc.

What are the main steps for a parametric study?

- System modeling: The power system must be modeled with the standard considerations for the phenomena to evaluate.

- Create the parameter variations: Establish variations for different parameters.

- Create scenarios: Assemble several parameter variations to create scenarios.

- Define the simulation variables to assess: Establish the simulation results to analyze and how to post-process them.

- Execute the simulations: Simulate each one of the different pre-defined scenarios and save the intended scopes for post-processing.

- Post-processing: Analyze the results to find the suitable parameters according to the needs.

What is EMTP® Parametric Studio?

Parametric Studio is a no-code based toolbox for automating parametric analysis with EMTP®. By defining variations in the power system devices, the user can perform sensitivity studies, assess contingency scenarios, and evaluate the impact of parameter uncertainties. Parametric Studio possesses several key features oriented to enhance speed and accuracy, such as:

- Parallel processing, making better use of computational resources

- Auto-initialization from the results of the EMTP® load-flow solver

- Can display up to 20M points to visualize the scopes results

- Automatic and scheduled scopes post-processing

Main benefits Parametric Studio provides

Challenge: Parametric studies can take a lot of time as they need to run many simulations sequentially.

Solutions: Parametric Studio uses parallel processing to perform multiple simulations at the same time.

Challenge: Creating different scenarios can be highly time-consuming, as the user typically needs to create hundreds or thousands of cases.

Solutions: Parametric Studio can create parameter variations using either statistical distributions or even just a list of predefined values, in just a matter of few clicks.

Challenge: Maintaining the integrity of the power system database is a crucial concern, as the base case may be corrupted while manually changing parameters.

Solutions: Parametric Studio stored the parameter variation list in a different file than the original database; by doing so, the variations are applied only during the simulations and these variations also can be imported in another database.

Challenge: Though automation may be performed by user-written scripts. Such scripts are time-consuming to write and prone to errors and inefficiencies. In addition, the user needs to know how to code in the specific programming languages integrated with the software.

Solutions: Parametric Studio provides a non-code tool that allows everyone to create variations and scenarios with a few clicks.

Challenge: During a parametric study, initial load-flow conditions may vary. Without proper initialization, the time-domain simulation may not reach a steady-state.

Solutions: Parametric Studio uses the EMTP steady-state and load-flow solvers to find the initial load-flow conditions for each simulation, initializing all grid state variables and allowing a flat-start initialization. There is no need to use a third-party tool to find these initial conditions.

Challenge: Analyzing a large amount of information can be challenging or require other tools to make a graphical comparison or calculate statistical results.

Solutions: Parametric Studio incorporates a new graphical tool optimized for visualizing a large set of signals, it also has data exporting functionalities and embedded post-processing functions.

Creating variations with Parametric Studio

With Parametric Studio, users can define multiple variations over device parameters (e.g., resistance on an RLC branch, closing/opening time on a switch). They can also create variations that change the system topology (e.g., connecting a line between different buses, connecting a fault at different locations). Finally, it can even create variations using other variations.

Variations set in Parametric Studio are created and stored as an additional database, which allows the user to reuse them in different studies and prevents unwanted modifications of the original database. This helps the user maintain the integrity of the base case information.

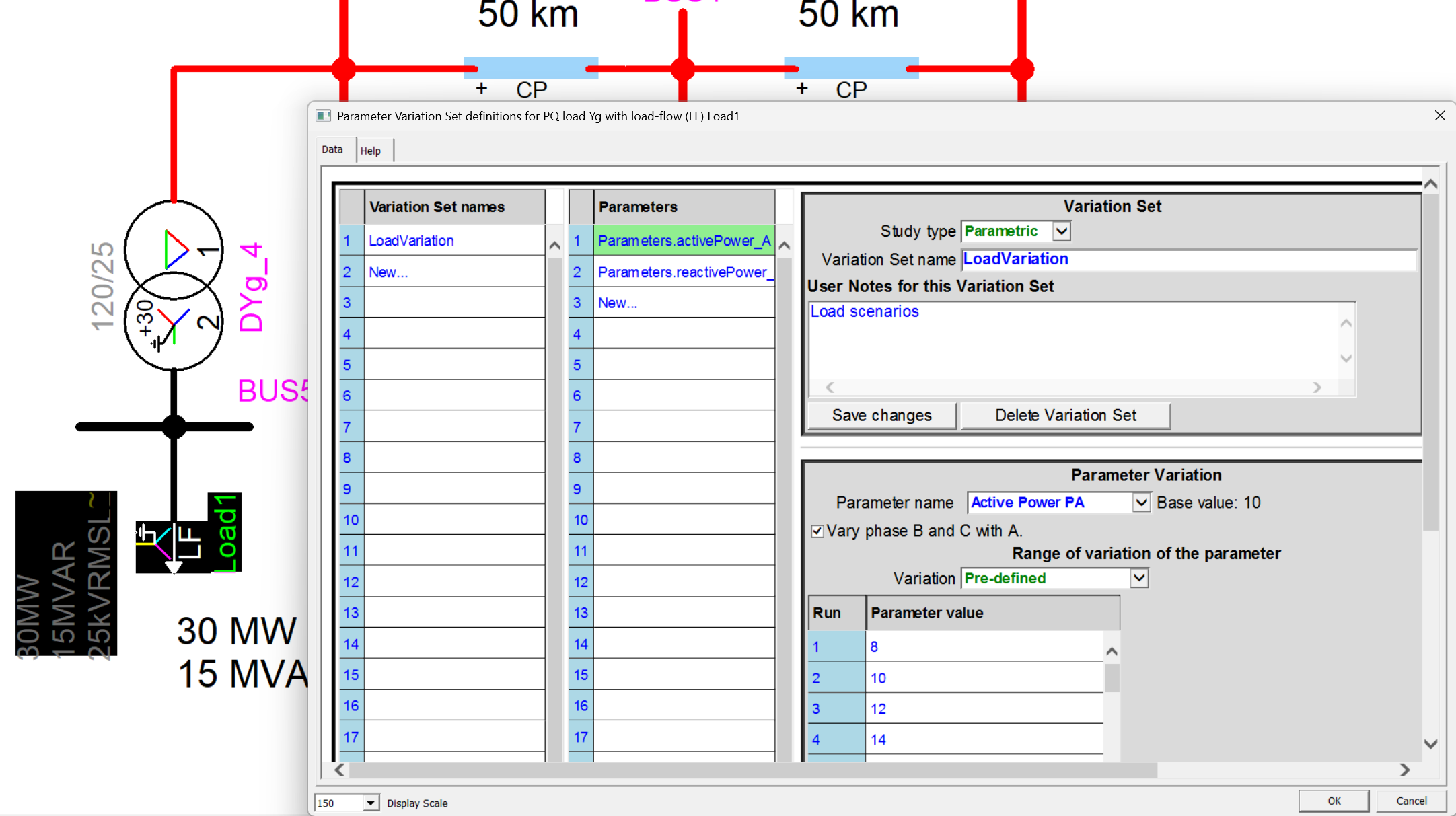

Figure 1. Device parameters creation – user creates or modifies parameter variation.

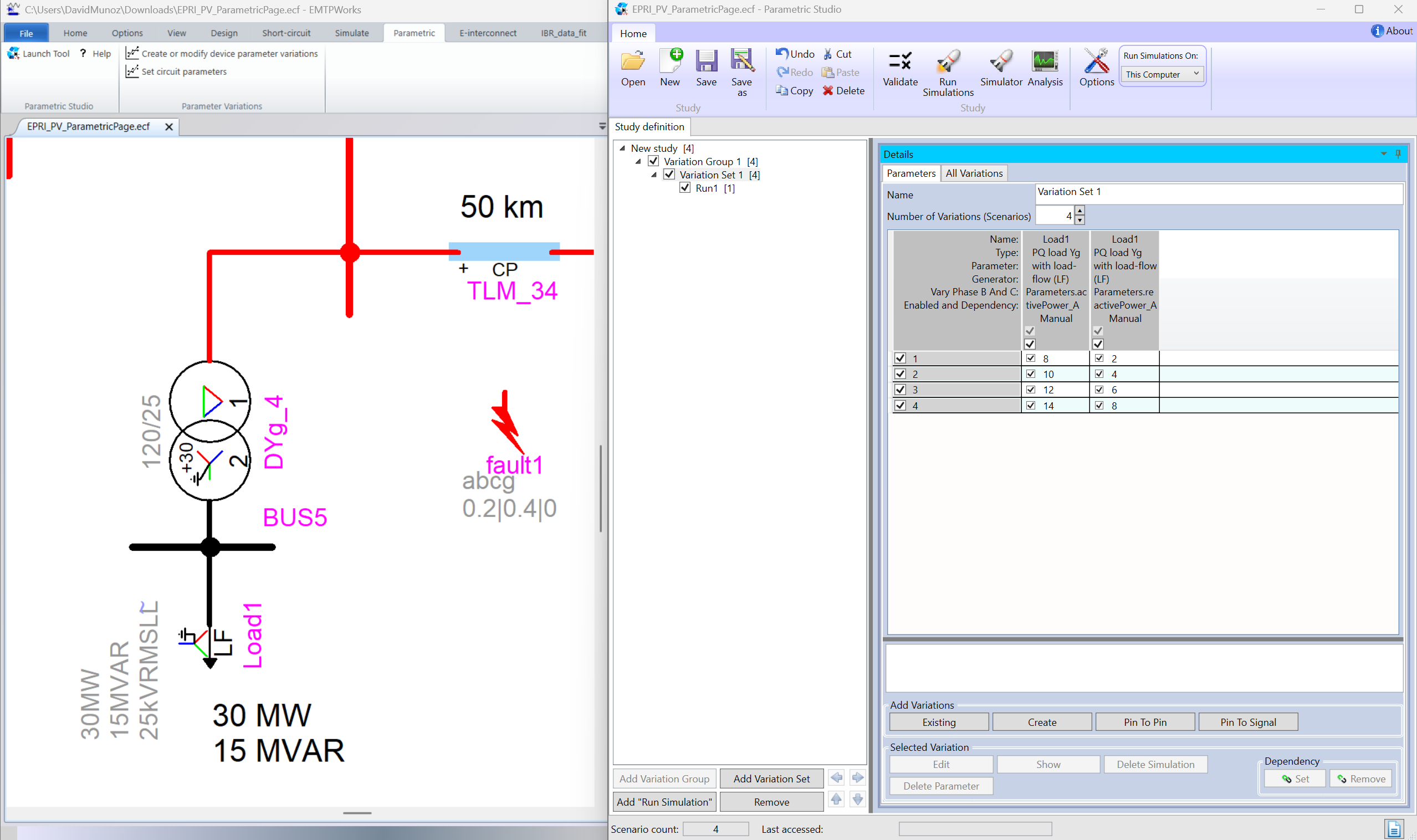

Once the user has created some variations, they can use them to make the list of scenarios to execute, as shown in Figure 2.

Figure 2. Parametric Studio – loading variations for the list of scenarios.

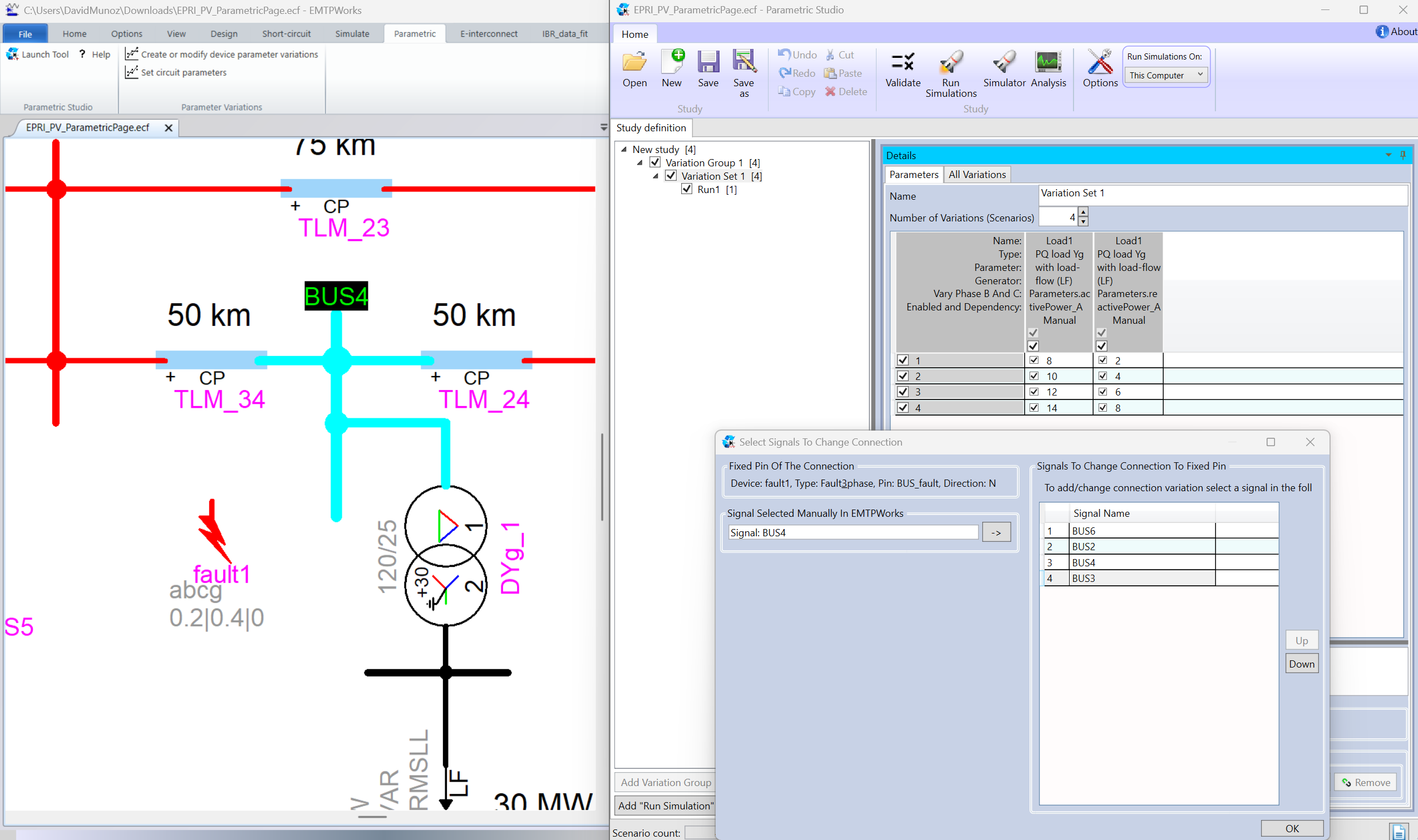

Users can also use the Parametric Studio to create a “Pin To Signal” variation, which allows users to set a list of different connection points for a device. This feature allows for evaluating the effect of having a device at various points in a power system and its impact.

Figure 3. Parametric Studio – Pin to signal variation set definition.

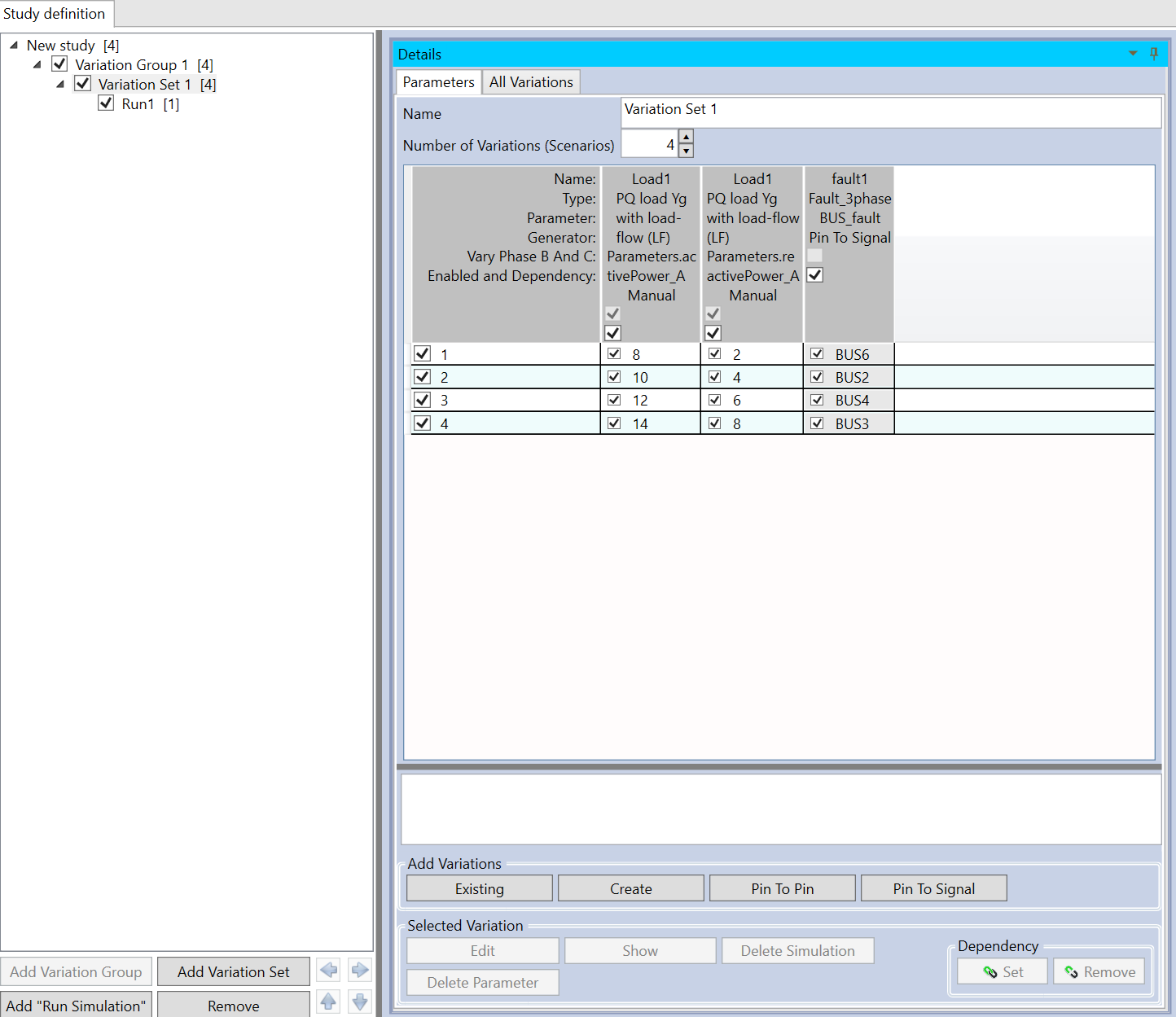

Following the procedure for creating and adding device variations, the user can create as many scenarios as desired. This workflow shortens the user's time for making custom cases. Figure 4 show the scenarios created based on the P and Q variations along the fault device location change.

Figure 4. Parametric Studio – creating scenarios with a combination of variation sets

Simulating the scenarios with Parametric Studio

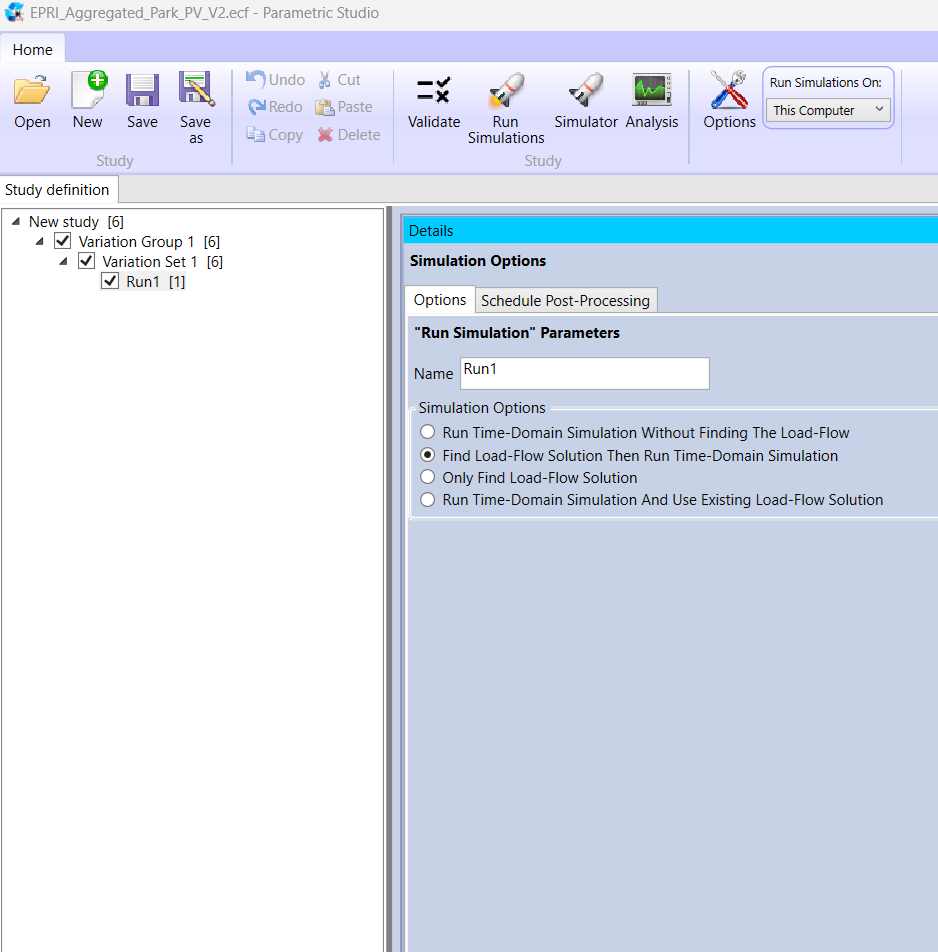

Parametric Studio not only allows setting different scenarios but also allows the execution of different types of simulations. In addition to that, as the EMTP® integrates a powerful unbalanced load flow solver, this feature can be used to initialize each time domain simulation after each variation, giving the user four simulation types to choose from.

- Time domain without load flow initialization: Automate time domain studies that don’t depend on load flow results, such as lightning studies changing tower footing resistance, lightning current, or transmission line geometry.

- Time domain with the load flow initialization: Automate time domain studies where load flow results impact event assessment, such as a large power system's dynamic stability changing the generation/load scenario and applying a set of disturbances.

- Static Load flow: Automate static studies such as contingency analysis, deactivating transmission lines, or modifying load active/reactive power configurations.

- Frequency scan: Automate frequency scans, as they are helpful on loci impedance assessments and when changing the location and size of power plants or compensation devices.

Figure 5. Parametric Studio - simulation types available

In addition, Parametric Studio can simulate several cases in parallel, assigning the simulation of one scenario to one CPU core (8, 16, cores). This ability means that parametric studies can be done in less time, and users can better exploit their computational facilities.

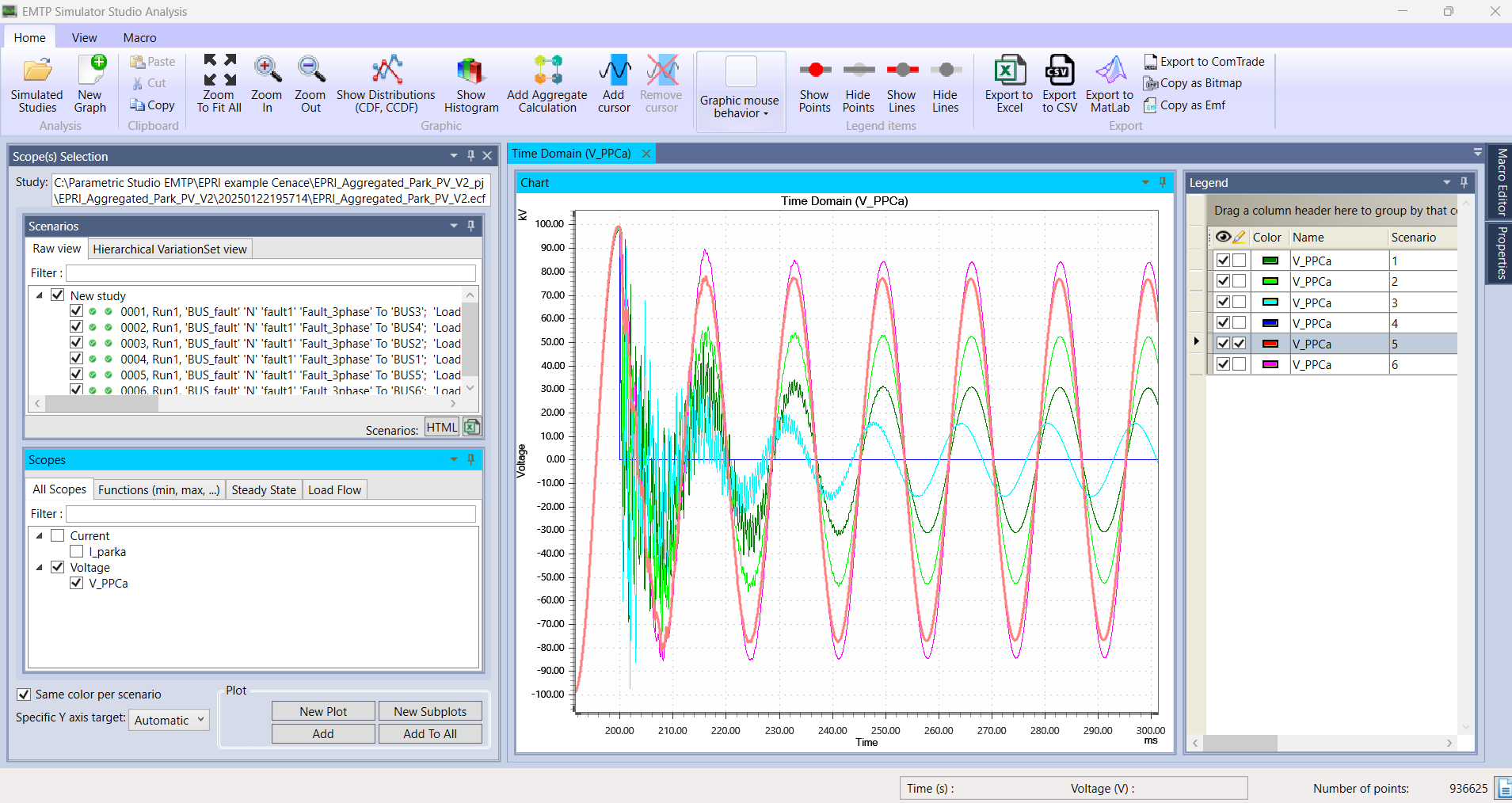

Post-processing the results with Parametric Studio

The Parametric studio has several key features that allow the user to set and process the results after all the performed simulations:

- The Analyzer tool is a powerful and efficient module that allows us to graph thousands of signals. This module has been tested for up to 20 million points

- Built-in ready-to-use post-processing functions like:

- “Export Min/Max”: Save the minimum and maximal values of a signal

- “Export When Threshold”: Returns true or false if a signal reaches a specific threshold and saves the time when it happens.

- “Export Stop Information”: Returns true or false if a simulation was stopped by a ‘Stop’ device and saves the time when it happens. A stop device is a logical device that allows the premature termination of a simulation before the simulation time is reached based on user-defined criteria.

- Export the selected results in different formats, such as COMTRADE (2013 and 1999 versions), MATLAB, CSV, and Excel, allowing users to use their preferred external tools for calculations or report preparation.

Figure 6. Analysis Studio - plotting selected scopes for the simulated scenarios.